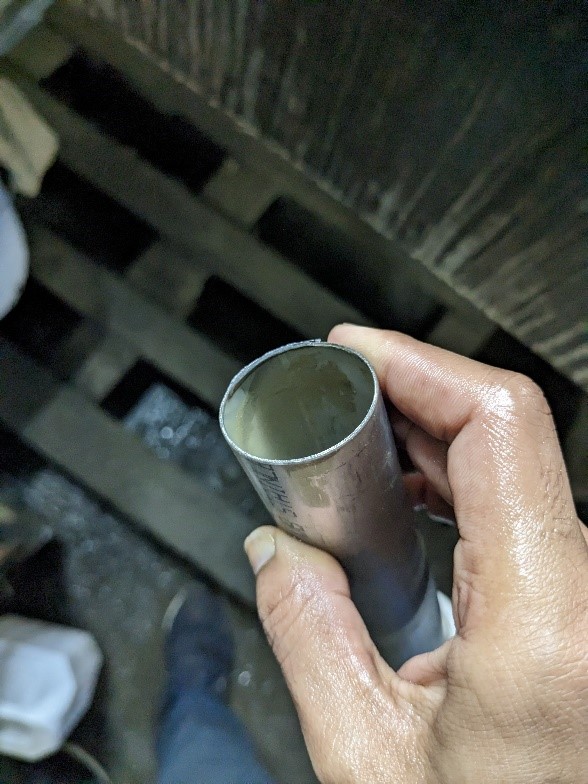

In the fast-paced world of automotive parts manufacturing, efficiency is key to staying ahead. Our customer, a prominent automotive parts manufacturer, faced a common challenge - the need to clean thousands of pipes daily after bending and cutting. Their existing cleaning process was time-consuming and posed safety concerns due to the use of hazardous cleaners. Seeking a better solution, they turned to Om Engineers for assistance.

1. The old cleaner they used required a high 10% concentration, leading to increased costs and additional waste.

2. Some pipes with extra burr and extra oil required manual brushing, prolonging the cleaning time and creating an inconsistent cleaning outcome.

3. Furthermore, the hazardous nature of the old cleaner raised safety concerns for their workforce.

1. Understanding the customer's specific requirements, Om Engineers developed Ecoclean-100, a highly effective and non-hazardous Neutral Cleaner.

2. This innovative solution was tailored to address the impurities commonly present on the pipes and offered a safe alternative for their cleaning process.

1. Enhanced Efficiency: Ecoclean-100 proved to be a faster cleaner, requiring significantly less time to clean the pipes compared to the customer's old sample.

2. Cost-Effective Solution: Ecoclean-100, only a minimal 5% concentration was required, leading to substantial cost savings for the automotive parts manufacturer.

3. Safety Assurance: Ecoclean-100 is non-hazardous neutral cleaner provided a safe working environment for the company's employees. Workers could now handle the cleaning process confidently, free from exposure to harmful chemicals.

1. Enhanced Efficiency in Deep Drawing and Blanking: Eco Draw 3051's high water solubility ensured smooth and efficient deep drawing and hole drilling operations. The lubricant paste significantly reduced friction during these processes, resulting in precise and high-quality metal components.

2. Versatility for Ferrous Metals and Aluminum: Eco Draw 3051 proved to be a versatile solution, suitable for use on both ferrous metals and aluminum. This versatility streamlined the company's metalworking operations, eliminating the need for multiple lubricants.

3. Cost-Effective and Dilutable: Eco Draw 3051's cost-effectiveness made it an economical choice for the metal fabrication company. Additionally, its dilutability with water provided the flexibility to adjust the lubricant concentration as needed for different applications, further optimizing resource utilization.